|

|

1-(800)-LOADTEC © 2012 Load Technology, Inc. All Rights Reserved |

LOADTEC ANNOUNCES ITS NEW HEADQUARTERS IN MESQUITE, NEVADA |

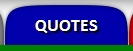

Our industrial coatings have now been completely revamped to supply a quality finish utilizing waterbased paints and solvent-free preparation materials. Hazardous chemicals previously used to etch and clean sheet metal have been replaced with phosphotizing cleaning systems and citrus-based degreasers. These environmentally-friendly products produce the same results as the previous chemicals used; however the hazardous chemicals have been eliminated from our facility with the same results achieved. The new facility also boasts a 300' long isolated coating/paint tunnel with a state-of-the-art paint booth and filtration system; complete with a custom-built paint mixing room. In-ground track rails can guide a specialized trolley fitted with an oversized ISO container, or a large steel base through the tunnel from cleaning, to coating, to drying in one complete, fluid movement. This isolated tunnel keeps any odors from entering the production areas and also keeps contaminants (dirt, dust, etc) from entering. The coating tunnel is also equipped with the necessary provisions to fully armor-coat trailer chassis and containerized load banks. The armor coating (elastomeric polyurethane coating) process has been greatly simplified and modernized for even greater results. |

LOADTEC is particularly proud to announce its new headquarters located in beautiful Mesquite, Nevada. This new production and office facility is the direct result of over 25 years of leading innovation and success in load bank manufacturing. We have combined our many years of experience and knowledge gained to plan, design, and construct a truly streamlined and efficient manufacturing plant to continue our commitment to providing the best load banks and products to meet and exceed our clients' needs. The 50,000+ square foot facility is situated on over 7 acres in an emerging industrial park just west of the Virgin River. This facility provides over double the production space of our previous facility in Las Vegas, NV. As part of our commitment to streamlining operations and environmental sustainability, we have also invested in building this site as an energy-efficient, solvent-free, environmentally-friendly production facility. Our Mesquite facility features all high-output fluorescent tube and CFL lighting, and highly-energy efficent interior and exterior lighting controlled by a central lighting computer which monitors the sunlight and occupancy of rooms and areas of the facility. Specialized solar lighting tubes in the production area's ceiling capture the natural sunlight and diffuses it into substantial worklight to reduce the need for extra lighting during daylight hours. Sensors located throughout the facility monitor the sun's position according to time of day, seasonal calendar, and amount of light existing in the area and adjust the number of light bulbs turned on and off at any given time. All production interior walls and surfaces are covered in a light-reflective coating to reflect any light towards the workspace areas. The exterior windows are specially glazed LOW-E glass to significantly reduce the sun's rays and to also effectivley reduce heating and cooling use/consumption. |

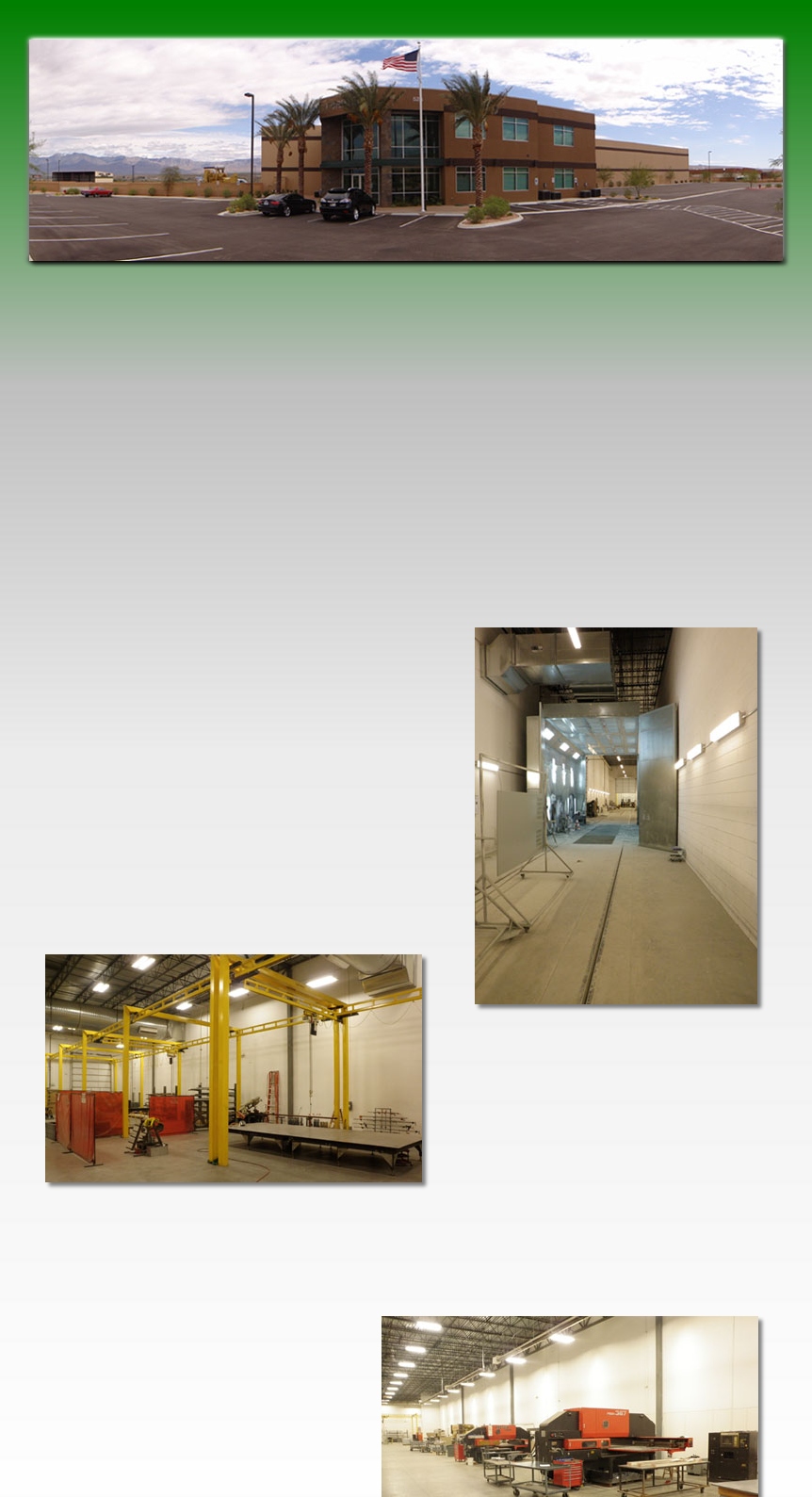

Our welding operations have also been improved with the installation of a large, heavy-lift (multi-ton) bridge crane allowing for greater ease and capability in manufacturing large steel bases, containerized load banks, and our full new line of trailer chassis for our trailer portable load banks. Our highly-trained welders are now AWS certified with over 20 years experience providing high-quality welds that have been subjected to x-ray scans and ultrasound technology to gain certification. |

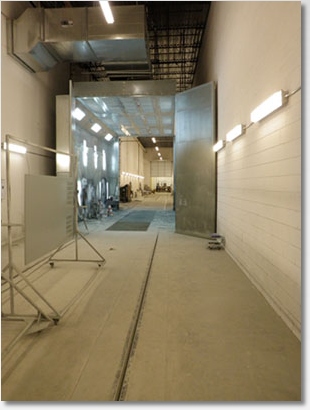

Our sheetmetal production area has tripled in size from our previous manufacturing facility. The increase in production space has allowed us to fabricate several thousand more pieces of metal through our production line. Our CNC punch presses can handle a 60" x 144" sheet of steel up to 1/4" thick. Our factory is staffed with CNC programmers that design all metal pieces, assemblies, and cabinetry in-house. The sheet metal production area is fitted with an independent concrete slab to absorb and supress vibrations. This independent slab |

aids in reducing vibrations and concussions that would normally be felt throughout a production facility. A sound barrier wall was also installed to absorb the sound produced by the metal fabrication equipment and to greatly reduce noise transfer to the assembly, offices, and other production areas. Completed metal assembly and storage areas were dramatically increased to allow for highly increased stock levels to help shorten lead times on equipment. Our assembly, wiring, and final production areas have nearly quadrupled in capacity and space. Four special bays were constructed to handle multiple large-caliber projects at the same time. These large production bays are specifically designed with no movement of the equipment required throughout the entire construction process, from start-to-finish. These large production bays are located in very close proximity to the large testing and diagnostics area, as well as the factory diesel generators utilized for testing. |

Office space has also increased dramatically. LOADTEC has been gradually working towards going paper-free. With the implementation of our new headquarters and new sophisticated network of servers, file storage, and data handling, we have been able to reduce paper usage by 90%. All brochures, invoices, manuals, literature, drawings, and training materials are now sent via email in PDF or another designated file type. Our goal is to become completely paperless within the next five years as we evolve with new production capabilities and systems to effectively eliminate the need for producing paper documents. Finally, this new headquarters facility was built with future growth and sustainability in-mind. The facility was designed to accomodate future expansion of adjacent facilities and amenities on the property as LOADTEC continues to grow. The Mesquite facility was the result of over 27 years of experiences, customer feedback, knowledge gained, bold ideas, and a desire to continue to be the industry leader and innovator in high-quality load banks and service. With this new facility, lead times have been decreased while improving customer support and quality. We are looking forward to demonstrating our new capabilities in providing a LOADTEC Load Bank for your next project's needs. |