|

|

1-(800)-LOADTEC © 2012 Load Technology, Inc. All Rights Reserved |

1984 - LOADTEC® is established and incorporated in December in La Mirada, CA under the founding goal to produce more reliable load banks to the market to better meet user requirements in a more compact form factor. |

1985 - LOADTEC® introduces the the first load resistor specifically designed for high-density power dissipation applications that do not require cool-down periods. This RESISTAR® Load Resistor revolutionized; and forever-changed, the load bank market. |

1985-1987 - LOADTEC® continues to develop and introduce new compact models of load banks implementing the new RESISTAR® load resistor design. The new models are extremely well-received in the marketplace and quickly adopted as the new standard in reliable and technologically advanced load banks for the time. |

1988 - LOADTEC® partners with another company to provide the first digitally-controlled Load Bank for the Army Corps of Engineers for automated and logged testing of rebuilt and re-qualified battflefield class generators. The applications include 50Hz, 60Hz, and 400Hz, as well as 28VDC aircraft start-cart generator testing. |

1985 |

1989-1992 - LOADTEC® continues to introduce new portable and permanently-installed load banks. These new models are produced with newly-emerging processor metering systems technologies which provide advanced metering and recording capabilties for the time. |

1992-1993 - LOADTEC® continues to experience increasing marketshare and production order volume due to the success of its products. A plan is implemented to relocate to Las Vegas, Nevada and plans for a new corporate headquarters and design are underway to double production and office space capacity. |

1993 - A site is identified in Las Vegas, NV and construction breaks-ground on the new LOADTEC® headquarters on 1.5 acres of land. |

1994 - The new Las Vegas Headquarters is completed and LOADTEC® begins its relocation and transition from Southern California to Las Vegas. |

1995 - LOADTEC® settles in to its new home in Las Vegas and begins to quickly makes use of its doubled production and staff capacity. A major project and investment is undertaken with the purchase of multiple CNC machine tools and CAD/CAM software implementation. LOADTEC® produces its first enclosure and all supporting metal pieces from the new Las Vegas Factory August 1, 1995. LOADTEC® operations are forever changed with unlimited capabilities to produce and expand its product line. |

1996 - LOADTEC® expands its portable load bank line to include trailer chassis manufactured in-house utilizing the new CNC Machine Tools and CAD/CAM Software Engineering. The CNC Machine Tools are capable of processing and handling steel up to 1/4" in thickness. |

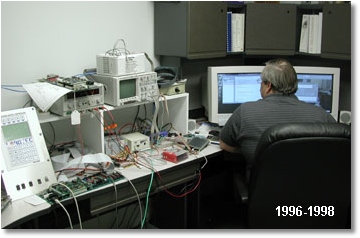

1996 - LOADTEC® identifies the need to develop a purpose-built digital control system in-house to address growing requirements for site and application-specific features not offered by any load bank manufacturer. This new digital control system would be a market viable and cost-effective solution to continue keep LOADTEC® ahead of its competion for many years to come. |

1997 - By mid-1997, the first development electronic circuit boards are designed and fabricated along with the first generation LOADTEC® Operation System, LTOS1. |

1998 - With the parallel devoplement testing of the control code and completion of the prototype circuit board assemblies for the digital control system, the new software and circuit boards were integrated into select load bank models for final testing. |

1999 - The first LOADTEC® Portable Load Bank ships from the factory containing the DP2-8600 Digital Control and Data Acquisition system. This release marks the first time a load bank is introduced to the world marketplace with a purpose-built, full digital control system. LOADTEC® again revolutionizes the load bank market with the DP2-8600 Fully Digital Load Bank Control & Data Acquisition system forever changing the load bank market. |

1999 - Following the huge success of the release of the DP2-8600 Digital Load Bank Control system; the "dot.com" phenomenon and telecom expansion with major data center construction taking place worldwide, LOADTEC® experiences highly increasing demand for its revolutionary new products. Plans are put underway to make another significant investment into LOADTEC's future. LOADTEC® breaks-ground on a facility expansion at the Las Vegas headquarters that will increase production and fabrication space by over 66%. |

2000 - After successful completion of the facility expansion, LOADTEC® moves the entire sheet metal fabrication division into the newly constructed space. Two additional CNC Machine Tools are added to accomodate the growing production and workload. |

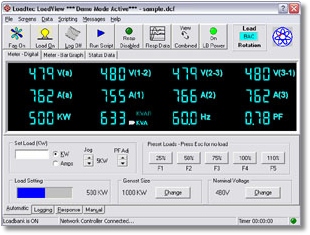

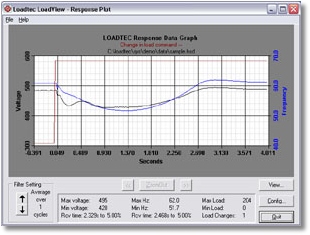

2000-2002 - After having had the DP2-8600 Digital Control System in the field for several years; gathering customer feedback along with new ideas and concepts for improvement, LOADTEC® begins in-house development on its Windows®-based LOADVIEW® PC Control/Data Logging & Scripting Software along with its accessory (HSR) High Speed Response Software Module. Also in concurrent development is a Windows®-based DLL interface to integrate LOADTEC® load banks into 3rd party application systems such as National Instruments' LABVIEW® System. ModBus protocol development also gets underway. |

2003 - LOADVIEW® PC Control/Data Logging & Scripting Software along with its accessory (HSR) High Speed Response Software Module is released, along with the Windows®-based DLL interface and ModBus RTU Interface. Development of LTOSII Operating Code ensues. |

2004 - Development begins on the second generation of LOADTEC® Digital Control Systems. The second generation of electronics' focus will aim towards permanently-installed LOADTEC® Load Banks. |

2004 - The Programmable Digital Controller (PDC) concept is born. Development of the PDC Controller begins to occur concurrently with an improvement on LOADTEC's operating code. The PDC will offer features to permanently-installed LOADTEC® Load Banks with functions such as Automatic Loading Operation to maintain a minimum load level, and Automatic Exercise Operation to provide scheduled load profile exercise of a generator. Also to be included is a Regenerative Control feature to absorb reverse power conditions from elevators, crane, and moving bridges. Automatic Loading and Automatic Exercise Operation will not be new features to LOADTEC®, but their implentation, installation, and execution into its digital control system will be the key advantage. |

2005 - The Programmable Digital Controller (PDC) is released and installed in many freestanding and radiator-mounted load bank models. The PDC offers not only several operational modes standardly-embedded in the controller, but also allows the capability of field-activation. |

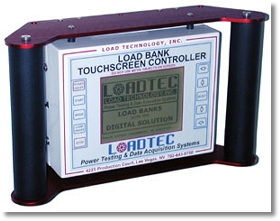

2005 - The successful DP2-8600 Digital Control System is retired from the portable load bank line and replaced with the new LOADTEC® TOUCHCOMMAND® O.I.P. Handheld TouchScreen Controller. The TOUCHCOMMAND® Controller raises the benchmark yet again by providing a self-powered portable touch screen controller with IP Ethernet capability and Intelligent |

Networking Control. The Intelligent Networking Control system allows the control of up to 32 LOADTEC® Load Banks to network together and function as ONE virtual load bank with one central controller running LOADVIEW® Software V4. LOADVIEW® Software Version 4 is also released with several improvements and updates. |

2006 - Following the tremendous success and integration of the PDC and TOUCHCOMMAND® Controller, LOADTEC® continues to witness substantial growth and demand for its one-of-a-kind, highly-reliable, rugged, and feature-rich load banks. Once again out-of-space to expand, LOADTEC® acquires over 7 acres of land to construct a new production and office headquarters in Mesquite, Nevada. The new facility will be the culmination of decades of operation, expansion, experience, knowledge, and the space and production facility needed to sustain future growth and success. |

2006 - Several months are spent researching, planning, drafting, and networking while conceiving the best new facility design for optimum production flow, workplace creative and ingenuity at the new LOADTEC® headquarters. Careful planning and attention-to-detail is exerted to allow for future expansion of LOADTEC's product line, production space, growth, and reliability in the marketplace. The new facility will feature several improvements over the previous facility, including a highly efficent "green" operating model to include the elimination of solvents used in coating processes, envrionmentally-friendly alternative cleansers, paper elimination, and cutting-edge machinery with a vast new computer network infrastructure including IP phone systems, voicemail to email, and on-call 24/7 technical support. |

2007-2008 - LOADTEC® breaks-ground on its new 7+ acre, 50,000+ square foot headquarters in Mesquite. Construction continues throughout 2007 into early 2008. |

2008 - The LOADTEC® trailer portable load bank line is fully redesigned to include a new rigid chassis, independent suspension equipped torsional axles, a removable skid portable load bank module portion built-in, plus a new Armorthane® Elastomeric armor coating that covers the complete trailer chassis. |

2008 - Constuction is completed and LOADTEC® begins its organized transition from Las Vegas to Mesquite. |

2012 - The new LOADTEC® V2 Website launches with interactive quote forms, an immense amount of information regarding all LOADTEC® models; including technical support, troubleshooting, and downloadable schematics, manuals, brochures, and photos, with the most up-to-date information available. |

2012+- LOADTEC® begins development on its third generation of electronics, operating code LTOSIII, and web-based load bank control from portable devices, cell phones, tablet PC's, etc. The investment in development will continue to keep LOADTEC® years ahead of its competion by creating new technological milestones with products to keep pace with the digital age and more demanding site specifications for its clientele. |