|

|

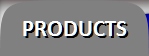

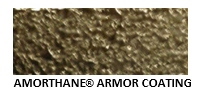

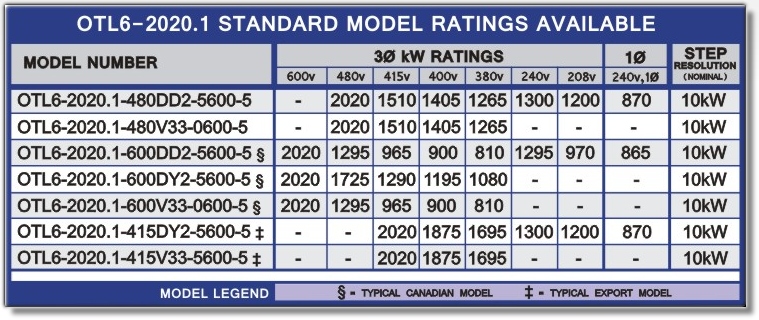

STANDARD GENERAL SPECIFICATION OVERALL DIMENSIONS: 216.0"L x 96.0"W x 102.0"H RESOLUTION: 10kW 4FREQUENCY RANGES: 50-60Hz Standard (contact factory for 400Hz rating) 4VOLTAGES: AC Standard (contact factory for DC voltage rating) 4RATINGS: >100% load guaranteed at rated voltage 4TOLERANCE: ±5% overall, ±2% balance 4AMBIENT: -20°F/-30°C to 120°F/50°C 4ALTITUDE: 4000 Ft. / 1200 M ENCLOSURE DETAILS 4RATING: NEMA 3R (Outdoor Weatherproof) 4CONSTRUCTION: Heavy Gauge Galvanized Steel w/ Complex Corner Engineering 4PAINT PREPARATION: SSPC Surface Prep. Std. #SP1 4PAINT PRIMER: Acrylic Direct-to-Metal (DTM) Primer on all Painted Surfaces 4PAINT FINISH: UV Resistant Premium High Performance Acrylic Enamel Paint for Abrasion & Grease/Oil Resistance 4PAINT COLOR: White (Standard) or Custom Color Optional † 4PROTECTION: Intake & Exhaust Doors w/ Safety Interlocks to prevent road spray infiltration during highway trailering 4DOORS: Interior Vent/Louver shields on doors to help prevent road spray infiltration during highway trailering 4LOAD RESISTORS: RESISTAR® Power Resistor independently mounted & installed in field-removeable trays for servicing/maintenance 4CONTROLLER: Integral Digital TOUCHCOMMAND® Touchscreen O.I.P. Controller 4CONTROL POWER SOURCE: Switch Selectable from the test source or external source 4CONTROL POWER: 24VAC derived from the selected 3Ø source via an installed internal control power transformer 4COOLING: (2) 7.5HP TEFC Sealed Bearing Motors (no lubrication required) - Forced air cooled by air foil propellers 4EXHAUST: HORIZONTAL Exhaust Air Discharge at 45° Upward Deflection 4ENCLOSURE LOUVERS: High-Temperature & Corrosion Resistant 4METERING: VM, AM, FM, KW, PF, KVA, KVAR, Rotation 4ALARMS: Air Flow, (3) Temperatures, OVLOAD, UFLOAD, OV/UVCNTRL, UFCNTRL, Cooling Motor Overload 4LOAD PROTECTION: Load sections individually fused 4LOAD CONTROL: Electrically held high duty cycle magnetic contactors 4MANUALS: Electronic O&M w/Drawings & BOM, with supplemental detailed operator controller instructions TRAILER DETAILS 4GENERAL: Dual (Tandem) Axle Heavy-Duty Highway Trailer with Steel Plate Deck, Fenders, and Safety Chains 4RATING (GVWR): XXXXXlbs (Gross Vehicle Weight Rating) Maximum Constructed Capacity 4DRY TOWING WEIGHT (GVW): XXXXX (nominal) without cables on reels 4AXLES/SUSPENSION: (2) Torsional Axles w/ Independent Suspension on each Wheel (no lubrication or maintenance required) 4LIGHTING: I.C.C. Compliant Lighting Package including brakes, reflectors, & license plate lighted bracket 4LIGHTING CONNECTOR: 3' Cable supplied w/ premium 7 pin flat blade connector 4WHEELS: 16" Trailer Wheel - 6 Bolt**** 4TIRES: Trailer Radial ST235/80R16 (E)**** 4BRAKES: Electric, (2) axle w/ Breakaway Safety Switch (controller not included) 4COUPLER: 2.31" (2-5/16)" Adj. Ball (standard) or Lunette Ring † (No-Cost Option) 4JACKS: (1) 6,000lb Telescoping Tongue, (2) Front & (2) Rear Corner Stabilizers 4FINISH COATING: Black ArmorThane® Heavy-Mil Polyurethane Armor Coating applied to entire trailer chassis 4CABLE REELS:(3)Heavy-Duty Manual Hand Crank Style w/Gear Reduction-capacity up to 850' of typical 4/0 type cable each w/ cam plugs 4DOCUMENTATION: Certified Manufacturer's Certificate of Origin from LOADTEC® Factory 4V.I.N. NUMBER: All LOADTEC® Trailer Portable Load Banks are provided with a unique and traceable VIN (Vehicle Identification Number) for global registration capabilites including the U.S.A, Canada, and Australia. LOADTEC has been assigned its own WMI (World Manufacturer Identification) number exclusive to LOADTEC® that is identifiable worldwide.***** 4ENGINEERING: The heavy-duty portable load bank trailer is purpose-built and engineered specifically for load bank trailering at the LOADTEC® factory. LOADTEC® does not purchase a third-party inexpensive utility trailer and modify it to accept a load bank as many of our competitors will. All LOADTEC® Trailer Portable Load Banks are over-engineered and designed with safety, versatility, durability, and are built-to-last with high quality materials. The weight of the trailer, load bank enclosure, cable reel(s), and accessories is carefully calculated, engineered, and distributed safely for maximum towing ease and capability. 4MANUF. COMPLIANCE: LOADTEC® is a fully licensed trailer manufacturer & registered with N.H.T.S.A (National Highway Traffic Safety Administration), D.O.T. (Department of Transportation), and the Society of Automotive Engineers (SAE®). LOADTEC® is also licensed with local, state, and federal government to manufacture trailers, and is also bonded and fully insured for trailer manufacturing. |

CLICK |

TARGETS TO VIEW FEATURES (POP-UPS & ACTIVE-X MUST BE ENABLED) |

OTL6 INTERACTIVE FEATURES MAP |

MODEL OTL6 SHOWN with OPTIONAL EQUIPMENT† |

MODEL BROCHURE |

ELEVATION DRAWING |

TOUCHCOMMAND® CONTROLLER |

Wi-Fi (TM) CAPABILITY** |

SAMPLE SPECIFICATION |

TECHNICAL DESCRIPTION |

GENERAL SUBMITTAL |

ADDITIONAL PHOTOS |

LOADTEC® ADVANTAGE(TM): HIGHLIGHTS STANDARD AND/OR OPTIONAL EQUIPMENT / FEATURES AVAILABLE EXCLUSIVELY WITH LOADTEC® LOAD BANKS |

LOADVIEW® & HSR Windows® Remote Laptop/Desktop Control Software † |

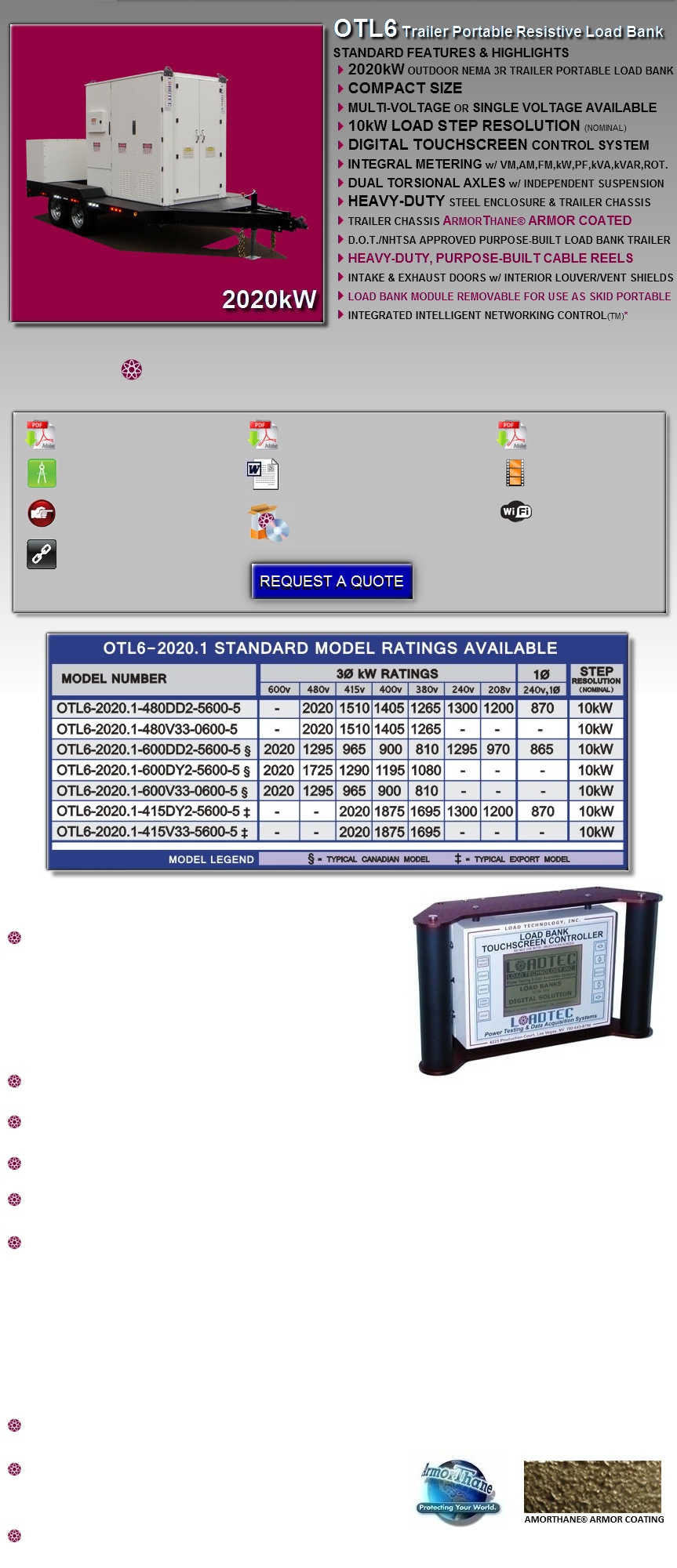

APPLICATION DATA 4USE: This model provides a complete, self-contained system for the testing of generators, UPS's, & other sources of varying kilowatt and voltage ratings. Typical users are generator set & electrical power equipment manufacturers. Other users are assemblers and installers to provide performance verification of their equipment. This portable unit is easily transported and moved on-site to provide a complete test system. This model also provides a complete, self-contained system providing the means of meeting NFPA 70, National Electrical Code Standard, Article 700-4 for the exercising and operational support of a standby/emergency generator set. A load bank sized for the "maximum anticipated load" of the facility will provide an optimum maintenance load in accordance with NFPA 70. It also fulfills the exercising requirements of NFPA 99 & 100. Load bank use also prevents "wetstacking." Wetstacking is a condition that can exist in diesel engines when all the fuel is not completely burned and passes into the exhaust system. In Diesel generators, wetstacking usually occurs because the engine is running at only a small percentage of its capacity; therefore the engine does not achieve its optimum operating temperature. Wetstacking may be detectable when there is a black oily residue exiting the exhaust, poor stability of the generator, or when poor generator frequency occurs. Wetstacking can shorten the life expectancy of a diesel generator engine. Utilizing a load bank to supplement the source load (or as the only test load) will help maintain the engine's optimum output rating and will eliminate wetstacking (if the load bank is properly sized). Load banks may also be of necessity for the diesel engine's oxidation catalyst (soot trap) system. Many air quality control districts require these emission reduction systems. In order for the oxidation catalyst system to function properly, the engine exhaust must be maintained at a minimum output temperature. The exhaust temperature must be maintained at the specific minimum level to regenerate the oxidation catalyst system to meet air quality standards. 4CONTROL: This load bank is controlled by an advanced dual processor embedded controller with integrated metering. The operator controls the load bank via an intuitive LOADTEC® Digital TOUCHCOMMAND® Touchscreen O.I.P. (operator interface panel) Controller with a monochromatic graphical LCD display for superior daylight operation. Upgrades to the latest control features can be achieved with a simple firmware upload. Multiple Resistive and/or Reactive LOADTEC® Load Banks equipped with the TOUCHCOMMAND® Touchscreen controller can be networked together to create a larger system with a single-point, intuitive & intelligent control*. The Touchscreen Controller requires only a single CAT 5 communication cable for connection and no additional control power is needed if located within 250 feet of the load bank. 4CONSTRUCTION: This load bank is designed and constructed for a long and reliable life in industrial environments. This model is constructed of heavy gauge galvanized steel w/ complex corner engineering that is primed with DTM acrylic enamel & painted using UV Resistant Premium High Performance Acrylic Enamel. The enclosure meets U.L. & Nema 3R outdoor weatherproof construction standards and is standardly provided with under-chassis tie-down rings, stainless steel and/or non-corrosive exterior hardware, and hinged access doors for connection & control compartments. All primed and painted parts are individually pre-painted before assembly; therefore there no blind unpainted surfaces exist helping to prevent internal corrosion from developing. The heavy-duty portable load bank trailer is purpose-built and engineered specifically for load bank trailering at the LOADTEC® factory. LOADTEC® does not purchase a third-party inexpensive utility trailer and modify it to accept a load bank as many of our competitors will. All LOADTEC® Trailer Portable Load Banks are over-engineered and designed with safety, versatility, and durability built-to-last with high quality materials. The weight of the trailer, load bank enclosure, cable reel(s), and accessories is carefully calculated, engineered, and distributed safely for maximum towing ease and capability. 4RESISTAR® LOAD RESISTOR: The RESISTAR® is designed specifically for high-density applications. The resistor is continuously- supported to minimize shorting contact with surrounding resistors. These resistors are terminated and supported with ceramic components; no plastic or polyester glass laminates are used. They are then independely mounted in trays that are easily removed in the field and serviced by a single individual. The resistors are conservatively designed, therefore the RESISTAR® does not require a cool down period and carries a standard; industry-exclusive, 3 year limited warranty. 4COOLING: This load bank is forced-air cooled by (2) direct drive airfoil propellers using (2) TEFC motors with disconnect and overload relay. These motors contain sealed bearings that do not require lubrication or maintenance during the life of the motors. 4PROTECTIVE CIRCUITS: The load bank is protected with fusing for each load section and control circuit. It is also provided with an airflow and temperature sensor to disconnect the load bank on a failure condition. Voltage and Frequency ranges are also monitored to protect the control power circuits and during alarm exercise failures. |

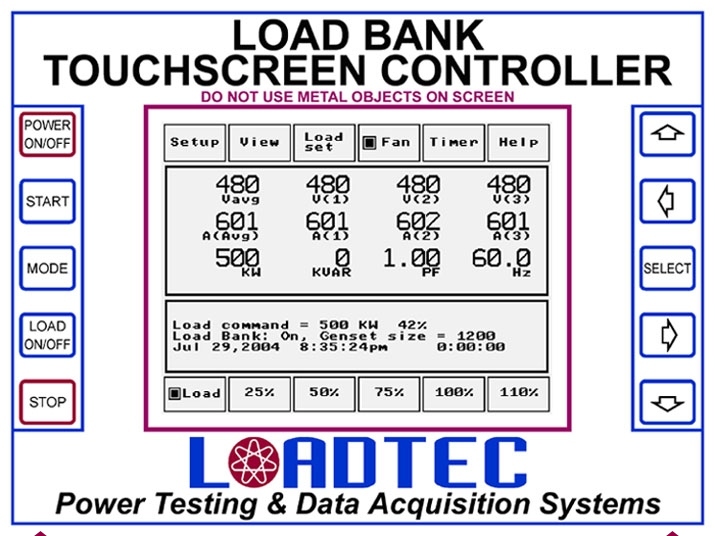

STANDARD EMBEDDED DIGITAL TOUCHCOMMAND® TOUCHSCREEN O.I.P. CONTROLLER FUNCTIONS, FEATURES, & HIGHLIGHTS |

FEATURES: 4Dual processer embedded control system 4Intuitive graphical Touchscreen LCD Display 4Transflective Monochrome Display for Superior Daylight Operation 4Heavy-Duty controller enclosure is shock-mounted 4Magnetic mounts installed for instantly attaching to metal surface 4Heavy mil Lexan screen protection 4Lightweight & rugged for maximum versatility & portability 4Controller detaches from integral mount for hand-held operation |

ADVANTAGES: The Digital TOUCHCOMMAND® Touchscreen Controller offers powerful & exclusive features unique to LOADTEC® Load Banks: 4Digital Data Communication 4Intelligent Networking System to connect up to (8) additional load banks* 4Network multiple load banks together to create a large system* 4Networking creates one single intelligent touchscreen point-of-control* 4Wi-Fi (TM) capability for WIRELESS Controller operation** 4Capability to upgrade to latest firmware releases 4TCP/IP Ready w/ RS232, RS422, & RS485 ports for custom configuration 4Integrates into 3rd party control systems(i.e. LabVIEW® or WonderWareTM) 4Multiple TOUCHCOMMAND controllers in different configurations can be linked together |

ACTUAL SIZE & SCREEN IMAGE OF TOUCHSCREEN CONTROLLER KEYPAD |

CONTROL FUNCTIONS: Simple, easy-to-use touchscreen interface allows for quick value changes & selections: 4Touch "kW" screen area for kW value & controller queries for new load value 4Control Power: ON-OFF 4Automatic Fan Start for Voltage & Rotation 4Direct kW or Amperage Load command input 4Direct PF command input (requires optional Reactive unit connected) 4JOG LOAD UP & DOWN adjustment by programmable value 4(5) Programmable LOAD STEP buttons by % of test source rating 4Load Step/Fan Compensation correction variables 4(16) Stage Programmable Test Sequencer 4Real-time clock and START/STOP Timer |

METERING: Metering is provided as an integral part of the TOUCHCOMMAND® Touchscreen O.I.P. Controller. A dedicated processor is provided for metering & data acquisition. THE FOLLOWING METERING VALUES ARE DISPLAYED: 4VOLTMETER: L1-2, L2-3, L3-1, Average 4AMMETER: L1, L2, L3, Average 4FREQUENCY: 45-440Hz 4KILOWATTS (kW) 4VOLT AMPS (kVA) 4KILOVARS (kVAR) 4POWER FACTOR (PF) ADDITIONAL FEATURES: 48kHZ Sampling, RMS Values past the 3rd harmonic 4Calibration Routine to match reference meters |

INTEGRATED PROTECTION SYSTEM: The Digital TOUCHCOMMAND® Touchscreen O.I.P. Controller provides a comprehensive protection system: 4All faults are displayed in a message area on the screen & recorded in an operation log for reference 4Faults will display on screen and shut-down and/or disconnect the load bank as required 4Temperature & Voltage Faults are monitored in two stages for pre-shutdown alarm 4Fan Operation & Air Flow are continuously monitored 4Exhaust, Intake, & internal temperatures are monitored 4Control VOLTAGE is monitored for over & under voltage in two stages 4Load OVER-VOLTAGE is monitored in two stages for pre-shutdown alarm 4Control FREQUENCY is monitored for over & under rating condition 4Cooling fan motor(s) overload monitored and alarmed 4Fuses are provided on each control and load circuit |

INTELLIGENT NETWORKING CONTROL(TM)*: The Digital TOUCHCOMMAND® Touchscreen O.I.P. Controller is provided with the embedded capability of connecting multiple LOADTEC® load banks together to create a larger intelligent testing system. 4Combine up to (8) additional Resistive, Resistive/Reactive, or Resistive & Inductive Modules together 4The TOUCHCOMMAND® controller automatically recognizes & properly configures the addition of each load bank 4All connected load banks' functions are combined to operate as if all the load banks were ONE single load bank 4The Intelligent Networking feature verifies that each connected load bank has the same phase connections 4One TOUCHCOMMAND® touchscreen controller provides a single-point of intelligent control for all connected units 4LoadVIEW® Windows Remote Laptop/PC Control Software† can also be interfaced to control the system |

LOADLINK® DLL Interface for LabVIEW® & WonderWare(TM) † |

DIGITAL TOUCHCOMMAND® TOUCHSCREEN O.I.P. CONTROLLER CONFIGURATIONS |

STANDARD INTEGRAL (LOCALLY-MOUNTED) DIGITAL TOUCHCOMMAND® TOUCHSCREEN O.I.P. (MOUNTED BEHIND NEMA 3R WEATHERPROOF HINGED DOOR CONVENIENTLY LOCATED ON LOAD BANK. THE TOUCHCOMMAND® CONTROLLER DETACHES FROM THE INTEGRAL MOUNT FOR HAND-HELD OPERATION IF DESIRED) |

OPTIONAL NEMA 4X PORTABLE WEATHERPROOF (SPLASH-PROOF) REMOTE CASE w/ DIGITAL TOUCHCOMMAND® TOUCHSCREEN O.I.P.† (PROVIDED "LOOSE" IN LIEU OF INTEGRAL O.I.P., OR AS AN ADDITIONAL O.I.P. CONTROLLER) |

OPTIONAL NEMA 1 HAND-HELD ADDITIONAL DIGITAL TOUCHCOMMAND® TOUCHSCREEN O.I.P.† (PROVIDED "LOOSE" AS AN ADDITION TO THE STANDARD INTEGRAL O.I.P. CONTROLLER) |

FOOTNOTES: † OPTIONAL ITEM(S) The "†" symbol is used throughout the entire website to note and identify any optional item, feature, or equipment not included in the standard base pricing of the load bank and/or equipment. These optional items are normally available for additional costs. *INTELLIGENT NETWORKING CONTROL(TM) Intelligent Networking Control is installed/embedded in the firmware of the Digital TOUCHCOMMAND® Touchscreen O.I.P Controller. To enable and utilize this function, additional compatible (LOADTEC® Load Bank(s) equipped with the Generation 2 Touchscreen Digital O.I.P. Controller) LOADTEC® Load Banks must be connected to a network-style router/switch. Compatible Resistive-only, Resistive/Reactive, or Inductive-only modules can be networked together in any combination to create a large testing system. This Intelligent Networking Control(TM) feature can be used together with Wi-Fi(TM) Connectivity** to achieve a wireless testing system with a single TOUCHCOMMAND® Touchscreen O.I.P Controller point-of-control. Please inquire with LOADTEC® for a list of tested & recommended network-style DHCP routers/switches that are recognized to be compatible with the TOUCHCOMMAND® Touchscreen O.I.P. controller's Intelligent Networking Control(TM). **Wi-Fi (TM) CONNECTIVITY & CONTROL The Wi-Fi(TM) connectivity and control feature is installed/embedded in the firmware of the Digital TOUCHCOMMAND® Touchscreen O.I.P Controller. To enable and utilize this function, Intelligent Networking Control(TM) must first be functioning. Second, an accessible wireless network must be provided through the use of the LoadVIEW® Software† running on a Windows® PC or Laptop. Please inquire with LOADTEC® for a list of tested & recomennded DHCP routers that are recognized to be compatible with the TOUCHCOMMAND® Touchscreen O.I.P. controller's Wi-Fi(TM) connectivity & control feature, LoadVIEW® Software † , & Wi-Fi (TM) Connectivity & Control. ***SPECIFICATION COMPLIANCE REVIEW LOADTEC® will make every effort possible in good-faith to help ensure the submitted specification, or the intent of the submited specification, is complied with. Major deviations or non-compliance will be noted in the Technical Description and/or as an addendum to the Technical Description of the quote/proposal offering. Many times specifications submitted contain contradictory information, pose exclusionary requirements, or requests that are extraordinary in nature. These unusual requests or conflicts of requests/information will cause forced deviations from the specifications, or non-compliance of particular sections, which LOADTEC® will note in the Technical Description and/or an addeundum to the specification of the quote/proposal offering. ****WHEELS & TIRES The image of the wheel design displayed is currently used in production of this trailer portable load bank. The actual wheel design and finish may differ from the image shown according to the wheel manufacturer's product offering and LOADTEC® stock levels at the time of load bank shipment from the factory. All LOADTEC® Trailer Portable load banks are supplied with wheels and tires suitable and designed for trailering applications. Wheel & tire size may differ from the information listed according to the wheel manufacturer's product offering and LOADTEC® stock levels at the time of load bank shipment from the factory. *****VIN/WMI/GOVERNMENTAL LAWS & RESISTRATION LOADTEC® provides each trailer portable load bank with a VIN number according to U.S. federal laws, rules, and regulations. LOADTEC® has received reports worldwide from customers advising successful local governmental acceptance/and or registration. LOADTEC® customers must independently verify (at their own expense) with their local, state, and/ or federal government/law enforcement regarding roadworthiness,importation legalities, rules, & guidelines. LOADTEC® does not guarantee or warrant legal conformance, suitability, or roadworthiness concerning international jurisdictions outside of the U.S.A. LOADTEC® trailer portable load banks conform to all applicable U.S. federal motor vehicle safety standards in effect at the time of production and shipment from the factory. LOADTEC® strongly urges customers to please obey and abide by all traffic laws and safety regulations in your jurisdiction. ******REMOVABLE SKID PORTABLE LOAD BANK MODULE This trailer portable load bank is supplied with a removable load bank module mounted to its own skid portable base. To remove the load bank module for use as a stand-alone skid portable load bank, 6 or 8 bolt assemblies (depending on trailer model) must be removed from underneath the trailer chassis. The skid portable load bank module can then be lifted out of the trailer chassis opening using the lifting eyes/brackets mounted on top of the load bank module enclosure. NEVER ATTEMPT TO LIFT THE ENTIRE CONNECTED TRAILER CHASSIS AND LOAD BANK TOGETHER USING THE LIFTING EYES ON TOP OF THE LOAD BANK ENCLOSURE. THE BOLT ASSEMBLIES THAT FASTEN THE LOAD BANK SKID PORTABLE MODULE TO THE TRAILER CHASSIS OPENING MUST FIRST BE LOOSENED AND REMOVED BEFORE ATTEMPTING TO LIFT THE LOAD BANK SKID PORTABLE MODULE OUT OF THE TRAILER CHASSIS OPENING. DISCLAIMER: All information contained within this website is provided as a courtesy to our customers and is subject to change without notice. LOADTEC® strives to post the most accurate, updated, and current information regarding our products and services. The information on this website should be deemed reliable; however not guaranteed. LOADTEC® reserves the right to correct any errors or ommissions regarding this site and/or any proposal offerings. Pictures displayed on the website are for illustrative purposes only and may depict or show (but not limited to) optional: items, equipment, colors, features, configurations, & arrangements that may or may not be available for an additional cost. Weights and dimensions shown are a close estimate and are deemed reliable, but may vary due to the addition of optional equipment and or minor production changes throughout the life of the particular load bank model. The pictures and information were accurate at time of website publishing to the world wide web. |

OPTIONAL ITEMS, FEATURES, OR EQUIPMENT † OPTION 1T: LOADVIEW® COMPUTER/REMOTE CONTROL, DATA LOGGING & SCRIPTING SOFTWARE The LOADVIEW® Software is a Windows® PC based control and Data Logging Package. LOADVIEW® Software provides full REMOTE load bank control and data acquisition on a PC based laptop or desktop computer via an RS-232 serial port. Data logging features allow the test to be recorded; reports to be customized, configurated, printed, and also exported to Microsoft Excel®. LOADVIEW® offers the ability to develop customized control screens with sounds, colors, graphics, & metering, all with an unlimited amount of screens to create. Scripting features also allow a customized test profile to be automated and configured to a specific project, jobsite, or customer's requirements. ...see more info on LOADVIEW® SOFTWARE INFORMATION LOADTEC® is the ONLY load bank manufacturer to offer an entire comprehensive software package with these powerful features combined. † OPTION 2T: HIGH SPEED RESPONSE (HSR) SOFTWARE MODULE (REQUIRES OPTION 1T) The High Speed Response Software Module (HSR) is utilized to determine source (generator) response to block load events captured using high speed data acquisition. The sampling period for the HSR software is 60 cycles pre-event, and 60 seconds of the actual event. Utilizing a logging rate of 8 Khz (1/cycle), the sampling rate is 160/cycle @ 50Hz. The total high speed samples can be displayed and printed in a tabular format or a graph with each value displayed as amplitude versus time. HSR Software is a compliment and additional software function that can be added to the LOADVIEW® Software. ...see more info on HIGH SPEED RESPONSE SOFTWARE LOADTEC® is the ONLY load bank manufacturer to offer a High Speed Response Software Event Capture System. † OPTION 3T: EXTERNAL CAM-DEVICE RECEPTACLE ARRAY An array of male, color-coded cam-devices, are provided externally with caps secured by lanyards, and are internally bussed to the main load bus to provide multiple 400amp quick-connects for the load connection cables. The quantity of external male cam-devices vary from load bank model-to-model depending on rating and capacity. The load bank is also provided with internal mechanical compression lugs to connect cables directly to the load bus. † OPTION 4T: SURGE BRAKES [IN LIEU OF STANDARD ELECTRIC BRAKES] A tongue-mounted surge brake with breakaway actuator is provided in lieu of the standard electric brakes. † OPTION 5T: SPARE TIRE**** The Spare Tire Option is provided with a pad-lockable under frame mount. The spare tire is a "full-sized" tire and wheel matching the axle wheels and tires. † OPTION 6T: (3) MOTORIZED CABLE REELS [IN LIEU OF (3) STANDARD MANUAL HAND-CRANK REELS] The Motorized Cable Reel option provides (3) motorized cable reels in lieu of the standard (3) manual hand-crank cable reels. All LOADTEC® Cable Reels are purpose-built, heavy-duty CABLE reels. LOADTEC® Cable Reels are not hose reels; they are rugged, durable, and built-to-last w/ gear reduction and black powder coat finish. The motorized cable reels are able to hold up to 850' of typical 4/0 cable (W) each w/ cam-device plugs. The motorized reels are provided with a foot pedal for operation and require a 120VAC power source to power the reels. The reel motors are hazardous-duty, heavy-duty motors rated to power the reels with a full load of cables. Cable and cable cam-devices not included. † OPTION 7T: CABLE REEL SECURITY ENCLOSURE The Cable Reel Security Enclosure option provides a heavy-gauge steel enclosure built around the cable reels. The enclosure is intended to provide security and theft-detterence for the high-value cable stored on the cable reels. The enclosure also offers the cables protection from the sun's harmful U.V. rays. The enclosure incorporates a hinged, pad-lockable access door which rotates upward 270° and rests on isolation bumpers on the top of the reel enclosure for easy access to the cable reels. Cable and cable cam-devices not included. † OPTION 8T: SINGLE PHASE (1Ø) CONTROL POWER (NOT AVAILABLE ABOVE 875kW) This option is not available on this specific model † OPTION 9T: EXTENDED WARRANTY TERMS In addition to the Standard Tier#1 Warranty supplied with every new load bank at time of shipment, additional extended warranty coverage period tiers are available for purchase up to 5 years from the date of factory shipment. These optional extended warranty tiers are available in PARTS ONLY, and PARTS & LABOR versions. ...see more info on EXTENDED WARRANTY TIERS INFORMATION † OPTION 10T: ADD ONE ADDITIONAL REMOTE DIGITAL TOUCHCOMMAND® TOUCHSCREEN O.I.P. CONTROLLER [CAPABILITY TO ADD UP TO (8) ADDITIONAL TOUCHCOMMAND® CONTROLLERS] An additional (extra) Remote Digital TOUCHCOMMAND® O.I.P. Controller is provided in addition to the standard, unit-mounted, Integral TOUCHCOMMAND® O.I.P Controller. This TOUCHCOMMAND® O.I.P Controller can be added in any one of the following configurations: (a) NEMA 1 Hand-Held Portable, or (b) NEMA 4X Portable Case. † OPTION 11T: NEMA 4X REMOTE PORTABLE CASE DIGITAL TOUCHCOMMAND® O.I.P. CONTROLLER [IN LIEU OF STANDARD INTEGRAL (UNIT-MOUNTED) LOCAL CONFIGURATION] The Digital TOUCHCOMMAND® Touchscreen O.I.P. Controller is provided in a NEMA 4X Weatherproof/Splash-proof Remote Portable Case as a substitute [in lieu of] for the standard integral (unit-mounted) local configuration. † OPTION 12T: LOADLINK® WINDOWS® DLL INTERFACE FOR LABVIEW(TM) & WONDERWARE® INTEGRATION The LOADLINK® Windows® DLL Interface License provides an interface for integration into software programs such as LabVIEW(TM) and Wonderware® (programming of system not included). ...see more info on LOADLINK DLL INTERFACE INFORMATION LOADTEC® is the ONLY load bank manufacturer to offer the LabVIEW & WONDERWARE DLL interface embedded in load banks. † OPTION 13T: SPECIFICATION COMPLIANCE*** LOADTEC® offers the availability of creating special and unique custom load bank solutions to meet extraordinary specifications supplied for a particular site or project. LOADTEC's® engineering department will review your specification and advise if we can offer possible solutions to special requirements and/or uncommon requests. LOADTEC® is the ONLY load bank manufacturer to offer the capability to add custom/specific features through software and firmware solutions. |

ULTIMATE VERSATILITY & ADAPTABILITY REMOVABLE SKID PORTABLE LOAD BANK MODULE The load bank module is mounted to its own skid portable base. The removable skid portable load bank module mounts inside an opening in the trailer chassis. The skid portable load bank module quickly and easily removes from the trailer chassis (remove 6 bolt assemblies) for use independent of the trailer chassis for ultimate versatility.****** |

1-(800)-LOADTEC © 2012 Load Technology, Inc. All Rights Reserved |