|

|

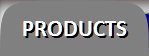

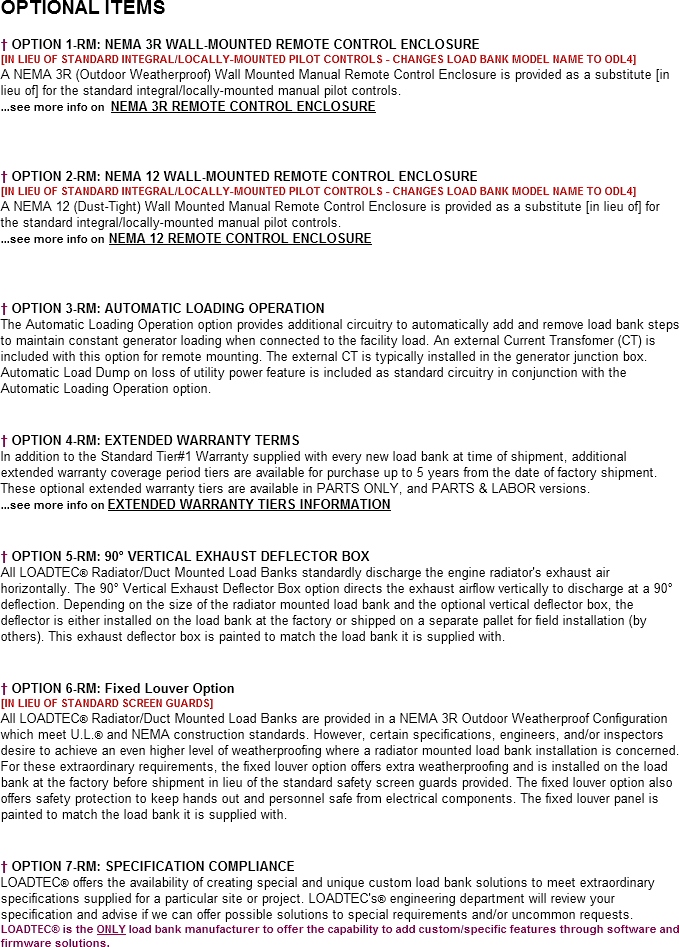

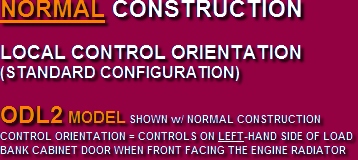

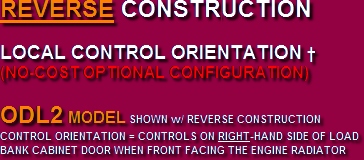

STANDARD FEATURES 410kW-1000kW @ 480V or 600V 3Ø 60Hz 410kW-500kW @ 208V 3Ø 60Hz 410kW-1000kW @ 380-415V 3Ø 60Hz 4SIZED TO MATCH RADIATOR CORE DIMENSIONS 4LOCALLY MOUNTED PILOT CONTROLS 4PAINTED TO MATCH ENGINE MANUF. COLOR 4RADIATOR ATTACHMENT & EXHAUST FLANGE 4REVERSIBLE CONTROL LOCATION ORIENTATION 4NEMA/OSHA SCREEN GUARDS 4NEMA 3R ENCLOSURE RATING w/ LIFTING EYES |

STANDARD RATINGS AVAILABLE: 4(U.S.A.): 10-1000kW @ 480V, 3Ø, 3W, 60Hz 4(U.S.A.): 10-500kW @ 208V, 3Ø, 3W, 60Hz 4(U.S.A.): 10-250kW @ 240V, 1Ø, 2W, 60Hz 4(U.S.A.): 10-1000kW @ 240V, 3Ø, 3W, 60Hz 4(EXPORT): 10-1000kW @ 380-415V, 3Ø, 3W, 50Hz 4(U.S.A./EXPORT): 10-1000kW @ 600V, 3Ø, 3W, 60Hz 4VOLTAGE RANGE: 208V to 600V 4FREQUENCY: 50Hz, 60Hz, or 400Hz (contact factory for 400Hz applications) GENERAL STANDARD SPECIFICATION: 4STEP RESOLUTION: 25%-50% (nominal) 4RECOMMENDED LOAD BANK kW % OF GENERATOR: 80% Maximum 4MAXIMUM LOAD BANK kW % OF GENERATOR: 100%* (not recommended) 4TOLERANCES: ±5% overall, ±2% Ø-Ø 4AMBIENT: -20°F/-30°C to +120°F/+50°C 4ALTITUDE: 4000 FT / 1200 M 4ENCLOSURE RATING: Nema 3R (Outdoor Weatherproof) 4CONTROL LOCATION: Integral / Locally Mounted Pilot Controls (Remote Optional †) 4CONTROL POWER: 24VAC (Transformer Supplied) 4PILOT CONTROLS: Control Mode Switch, Load Step Switch(es) as required, Load Step Indicator(s) w/ Lamp(s) as required 4PAINT PREPARATION: SSPC Surface Prep. Std. #SP1 4PAINT FINISH: UV Resistant Premium High Performance Acrylic Enamel 4PAINT COLOR: Painted to Match Major Manufacturer Engine Color 4COOLING: Forced Air by Engine Radiator Fan 4LOAD RESISTORS: RESISTAR® Power Resistor, Continuously Held 4POWER CONTROLS: Electrically Held Contactors w/ Fuses 4ENCLOSURE: Galvanized Steel with Stainless Steel and/or Corrosion Resistant Exterior Hardware 4WARRANTY: Tier #1- (1) Year Standard Limited, (3) Years Resistors 4EXHAUST: Horizontal Exhaust Air Discharge through protective NEMA/OSHA screen guards 4MANUALS: Electronic O&M w/Drawings & BOM 4ORIENTATION: Control Orientation can be easily reversed at the factory or in the field switching the screen guard and attachment flange sides PROTECTION: 4FUSED: Load & Control Circuits 4TEMPERATURE: Resistor & Control Section |

FOOTNOTES: † OPTIONAL ITEM(S) The "†" symbol is used throughout the entire website to note and identify any optional item, feature, or equipment not included in the standard base pricing of the load bank and/or equipment. These optional items are available for additional costs. *LOAD BANK kW PERCENTAGE RATING IN RELATION TO GENERATOR RATING The primary reason to include a Load Bank is to exercise and support the generator operation based on the sites specific requirement. A 60-80% Load Bank is typically more than adequate. NFPA 70, NEC code requires testing on the EPSS at anticipated connected load on a schedule. Typically a generator is not sized at smaller than 80% of the anticipated connected load. LOADTEC® generally does not recommend a 100% rated Radiator Mounted unit since the site has already been performance proven at original acceptance by external Load Banks to prove 100% performance. After proving the installation, the primary use of the Load Bank is to provide a tool for maintenance and operational support loading. There is no practical reason to test at 100% for routine exercising. LOADTEC® also does not recommend installation of 100% rated Radiator/Duct Mounted Load Banks without special considerations as well. The following conditions should be reviewed at bare minimum: 1) Is the radiator sized to provide engine cooling at 100% load at rated operating ambient and altitude? 2) Will the radiator cooling fan still deliver the required cooling air flow with the increased static pressure ( approx. .15" W.C. max. ) imposed by the load bank? 3) The radiator should be sized at least 5-10% overrated to compensate to radiant heat from the load resistors if the Load Bank is mounted within 12" of the radiator core. Even if the previous conditions are compensated for, the radiator may not provide enough core height and width to accomadate the required number of load resistors. **INSTALLATION NOTES Installation is not included or offered with any LOADTEC® Load Bank. Installation may require licensed personnel and/or a contractor according to local jurisdictional requirements. If the LOADTEC® customer does not provide detailed information regarding the mounting holes for the engine radiator, the load bank radiator flange will be provided "blank" for drilling flange holes that line up with the radiator mounting holes in the field (by others). Please note that any load bank manufacturer's radiator mounted load banks cannot be used on a typical factory sound-attenuated enclosed generator package. These packages typically have covers over the radiator opening with the engine silencer mounted in front of the radiator cores. These obstacles do not allow the installation of the Load Bank in the radiator air stream for cooling. Please inquire with the factory regarding the compability of a LOADTEC® Radiator Mounted Load Bank with a factory standard sound enclosure. Upon providing a drawing of the sound enclosure to LOADTEC®, we will be able to determine the capability and/or offer alternative solutions to fit our customers' specific needs. DISCLAIMER: All information contained within this website is provided as a courtesy to our customers and is subject to change without notice. LOADTEC strives to post the most accurate, updated, and current information regarding our products and services. The information on this website should be deemed reliable; however not guaranteed. LOADTEC reserves the right to correct any errors or ommissions regarding this site and/or any proposal offerings. Pictures displayed on the website are for illustrative purposes only and may depict or show (but not limited to) optional: items, equipment, colors, features, configurations, & arrangements that may or may not be available for an additional cost. Weights and dimensions shown are a close estimate and are deemed reliable, but may vary due to the addition of optional equipment and or minor production changes throughout the life of the particular load bank model. The pictures and information were accurate at time of website publishing to the world wide web. |

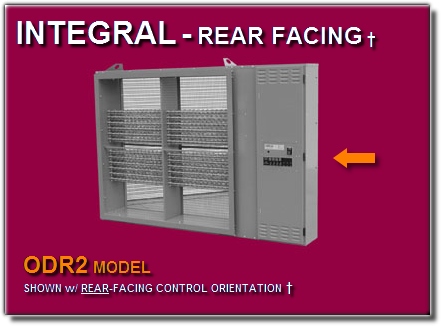

APPLICATION DATA 4USE: This model provides an economical alternative to a freestanding load bank for meeting NFPA 70, National Electrical Code Standard, Article 700-4 for the exercising and operational support of a standby/emergency generator set. The load bank is typically recommended to be installed outdoors allowing the heat produced to be discharged into the atmosphere. A load bank sized for the "maximum anticipated load" of the facility will provide an optimum maintenance load in accordance with NFPA 70. It also fulfills the exercising requirements of NFPA 99 & 100. Load bank use also prevents "wetstacking." Wetstacking is a condition that can exist in diesel engines when all the fuel is not completely burned and passes into the exhaust system. In Diesel generators, wetstacking usually occurs because the engine is running at only a small percentage of its capacity; therefore the engine does not achieve its optimum operating temperature. Wetstacking may be detectable when there is a black oily residue exiting the exhaust, poor stability of the generator, or when poor generator frequency occurs. Wetstacking can shorten the life expectancy of a diesel generator engine. Utilizing a load bank to supplement the source load (or as the only test load) will help maintain the engine's optimum output rating and will eliminate wetstacking (if the load bank is properly sized). Load banks may also be of necessity for the diesel engine's oxidation catalyst (soot trap) system. Many air quality control districts require these emission reduction systems. In order for the oxidation catalyst system to function properly, the engine exhaust must be maintained at a minimum output temperature. The exhaust temperature must be maintained at the specific minimum level to regenerate the oxidation catalyst system to meet air quality standards. 4SIZING*: The primary reason to include a Load Bank is to exercise and support the generator operation based on the sites specific requirement. A 60-80% kW rated Load Bank (in relation to generator kW rating) is typically adequate. NFPA 70, NEC code requires testing on the EPSS at anticipated connected load on a schedule. Typically a generator is not sized at smaller than 80% of the anticipated connected load. LOADTEC® generally does not recommend a 100% rated Radiator Mounted unit since the site has already been performance proven at original acceptance by external Load Banks to prove 100% performance. After proving the installation, the primary use of the Load Bank is to provide a tool for maintenance and operational support loading. There is no practical reason to test at 100% for routine exercising. If a 100% radiator mounted load bank is insisted upon, LOADTEC® still does not recommend installation of 100% rated Radiator/Duct Mounted Load Banks without reviewing special considerations and the following conditions at bare minimum: 1) Is the radiator sized to provide engine cooling at 100% load at rated operating ambient and altitude? 2) Will the radiator cooling fan still deliver the required cooling air flow with the increased static pressure (approx. .15" W.C. max.) imposed by the load bank? 3) The radiator should be sized at least 5-10% overrated to compensate to radiant heat from the load resistors if the Load Bank is mounted within 12" of the radiator core. Even if the previous conditions are compensated for, the radiator may not provide enough core height and width to accomadate the required number of load resistors. 4INSTALLATION**: The load bank is quickly and easily installed on the exhaust side of the engine radiator. The load bank can also be integrated into the actual exhaust plenum ductwork as an alternate installation method. The radiator mounted load bank is dimensionally matched to the radiator core and provided with a mounting flange that bolts to the radiator. This unit is typically installed and cabled by the generator set packager which provides a complete system without costly site construction requirements. The manual pilot controls are standardly integrated and installed locally to the load bank control access door. An optional wall-mounted remote control enclosure † is available in select form-factors (in lieu of locally-integrated pilot controls) as detailed in the option list below. 4OPERATION: The load bank is a complete system with pilot controls and devices to manually load a power source. Circuitry provisions are supplied in the load bank to interface to an automatic transfer switch, or other control circuitry, to disconnect the load bank on loss of utility power. An optional Automatic Loading † operational scheme is available. 4CONSTRUCTION: The load bank is designed and constructed for a long and reliable life in industrial environments. The load bank is constructed of galvanized steel that is primed & painted using UV Resistant Premium High Performance Acrylic Enamel. The enclosure meets U.L. & Nema construction standards and is standardly provided with radiator attachment flange(s), overhead lifting provisions, protective screen guard, exhaust plenum attachment flange, structural base mounting provisions, stainless and/or corrosion-resistant exterior hardware, and hinged access door for connection & control compartment. There are also optional control orientations to meet the installation requirements. 4RESISTAR® LOAD RESISTOR: The RESISTAR® is designed specifically for high-density applications. The resistor is continuously- supported to minimize shorting contact with surrounding resistors. The resistors are terminated and supported with ceramic components; no plastic or polyester glass laminates are used. The RESISTAR® does not require a cool down period and has a standard industry-exclusive 3 year limited warranty. 4COOLING: The load bank is forced-air cooled by the generator/engine radiator fan. 1500FPM Typical Flow. 4PROTECTIVE CIRCUITS: The load bank is protected with fusing for each load section and control circuit. It is also provided with a temperature sensor to disconnect the load bank on an over-temperature failure condition. The load bank's cooling airflow is inherently present whenever the engine is running and generating a power output. |

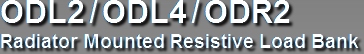

MANUAL PILOT CONTROL FEATURES & OPTIONS |

MANUAL CONTROL INTEGRAL CONFIGURATIONS AVAILABLE |

LOADTEC® ADVANTAGE(TM): HIGHLIGHTS STANDARD AND/OR OPTIONAL EQUIPMENT / FEATURES AVAILABLE EXCLUSIVELY WITH LOADTEC® LOAD BANKS |

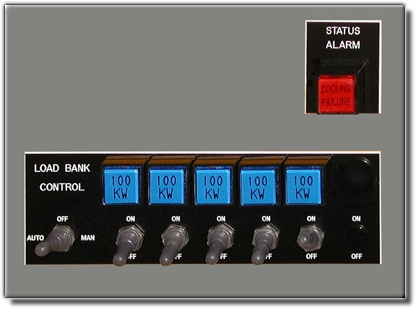

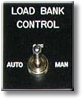

MANUAL CONTROL STANDARD FEATURES: Features included standard: 4INDIVIDUAL LOAD STEP SWITCH(ES) AS REQUIRED 4INDIVIDUAL LOAD STEP LAMP INDICATOR(S) AS REQUIRED 4COOLING FAILURE LAMP INDICATOR |

TRANSFER SWITCH INTERFACE: 4A contact interface is provided to indicate the position of the transfer switch to disconnect on loss of utility power. |

AUTOMATIC LOADING OPERATION †: The Optional Automatic Loading Operation feature provides circuitry and sensors to automatically add and remove load steps to maintain a constant generator load. This feature maintains a minimum load for changing connected loads. An external Current Transformer (CT) is provided according to the generator rating. |

FOR PROJECTS WITH A MORE DEMANDING SITE SPECIFICATION, THE FOLLOWING ADDITIONAL FEATURES ARE SUPPLIED STANDARD ON RADIATOR/DUCT MOUNTED MODEL ODSR / ODRR with Programmable Digital Controller: 4DIGITAL METERING: not available on Model ODL2/ODL4/ODR2 with manual controls. For specifications/applications where digital metering is desired, please see Radiator Mounted Load Bank Model ODSR w/ Programmable Digital Controller (PDC) [see more info on MODEL ODSR/ODRR] 4AUTOMATIC EXERCISE: not available on Model ODL2/ODL4/ODR2 with manual controls. For specifications/applications where Automatic Exercise Operation is desired, please see Radiator Mounted Load Bank Model ODSR w/ Programmable Digital Controller (PDC) [see more info on MODEL ODSR/ODRR] 4AUTOMATIC LOADING: available as a stand-alone option on Model ODL2/ODL4/ODR2 with manual controls. The Automatic Loading feature is embedded as standard equipment with the Radiator Mounted Load Bank Model ODSR w/ Programmable Digital Controller(PDC) [see more info on MODEL ODSR/ODRR] 4REGENERATIVE ABSORPTION: not available on Model ODL2/ODL4/ODR2 with manual controls. For specifications/applications where Regenerative Absorption is desired, please see Radiator Mounted Load Bank Model ODSR w/ Programmable Digital Controller (PDC) [see more info on MODEL ODSR/ODRR] 4BASE LOADING: not available on Model ODL2/ODL4/ODR2 with manual controls. For specifications/applications where Base Loading Operation is desired, please see Radiator Mounted Load Bank Model ODSR w/ Programmable Digital Controller (PDC) [see more info on MODEL ODSR/ODRR] |

ELEVATION DRAWING |

SAMPLE SPECIFICATION |

TECHNICAL DESCRIPTION |

GENERAL SUBMITTAL |

ADDITIONAL PHOTOS |

NEMA 3R WALL MOUNTED REMOTE CONTROL ENCLOSURE† (OUTDOOR WEATHERPROOF) |

NEMA 12 WALL MOUNTED REMOTE CONTROL ENCLOSURE† (DUST-TIGHT) |

MANUAL CONTROL OPTIONAL REMOTE † CONFIGURATIONS AVAILABLE |

MODEL BROCHURE |

1-(800)-LOADTEC © 2012 Load Technology, Inc. All Rights Reserved |